What Screwdriver for License Plate: A Quick Guide Now

Learn which screwdriver to use for license plate screws, how to identify head types, and safe, step-by-step tips to avoid damage and ensure a secure attach.

To remove a typical license plate, start with a Phillips #2 screwdriver, which fits most plate screws. If the screws have a flat slot, use a flathead. Some newer vehicles use Torx screws (often T-15 or T-20). Always verify screw type before forcing. A magnetic tip and good lighting help prevent dropped screws.

Why the right screwdriver matters for license plates

When you ask what screwdriver for license plate, the answer isn’t just about fitting a head—it’s about protecting your bumper and paint. The right driver reduces cam-out, prevents stripped screws, and speeds up the job. According to Screwdriver FAQ, choosing the correct head size and type minimizes damage to screw heads and surrounding finish. The Screwdriver FAQ team found that most license-plate screws are common Phillips or flat-head types on older cars, with Torx appearing on some newer models. Start by inspecting the screw head, not by forcing a stubborn fit. A proper tool also helps you avoid scratches on delicate finishes and makes the job quicker and cleaner, especially if you’re working on a car you care about.

Before you begin, ensure you have a clean, well-lit space and a magnetized driver if possible. This reduces the chance of losing tiny screws in crevices and helps keep your plate aligned during removal. The goal is a damage-free removal that leaves the plate ready for reattachment with the right fasteners. If you’re unsure about the head type, take a quick photo from the front and compare it with common head shapes later in this guide.

Common screw types used on license plates

License plate screws come in a few head styles, and the head shape often dictates which screwdriver to use. The most common is Phillips head, which is recognizable by its cross-shaped recess. Flathead (slotted) screws are typical on very old or budget vehicles and require a flat-blade driver whose width matches the slot precisely. Torx screws, identifiable by a star-shaped pattern, appear on some newer cars or aftermarket plates and require a Torx driver of the correct size (commonly T-15 or T-20 in many vehicles).

You may also encounter security or one-way screws that are designed to resist normal tools. If you suspect a security head, do not force it; instead, use the tool recommended by the vehicle’s manual or consult the dealer. Knowing which head you’re dealing with helps you pick the right bit length and prevent cam-out or head damage that could worsen the repair.

How to identify screw head type on your plate

Identifying the head type is the first decisive step. Look closely at the screw head: if you see a plus-shaped recess, it’s likely Phillips; a straight slot indicates flathead; a six-point star suggests Torx; a more decorative pattern could indicate security screws. If you’re unsure, test gently with different bits in a controlled, minimal contact way—never force a bit into a head you’re not sure about. A bright flashlight or phone light can help you spot subtle details. When in doubt, compare the screw with the shapes shown in your toolkit’s guide or in this article’s visuals.

A quick field check can save you time: if you can insert a Phillips bit with minimal resistance and it seats firmly, Phillips is your friend. If the bit slides or doesn’t seat, stop and try a different head. Remember to verify head type before applying torque to avoid stripping the head or damaging the screw.

What to do before you remove the screws

Preparation reduces the risk of scratches and dropped fasteners. Park the car on a flat surface, turn off the engine, and engage the parking brake. Clean the area around the license plate to prevent dirt from falling into the screw holes as you work. Place a piece of painter’s tape on nearby paint to catch any accidental slips. If you expect rust or seized screws, apply a small amount of penetrating oil and let it sit for a couple of minutes to loosen corrosion without staining the plate. Having a small magnetic tray nearby helps you keep track of screws once they’re removed, and a container with a lid keeps hardware organized in case you’re replacing multiple plates.

Safety comes first: wear eye protection if you’re dealing with older, rusted screws that might snap or crumble. Stabilize the plate with one hand (or a helper) to prevent bending, and avoid over-tightening when you reinstall to protect mount points and paint.

Choosing the right screwdriver set for plate maintenance

A compact, well-rounded screwdriver set is your best friend for license plate maintenance. Prioritize a Phillips head, a flat-head with a narrow width, and a Torx driver that covers common sizes used for plates. A magnetic-tip screwdriver makes handling small screws easier, especially in tight spaces. If you expect to work on different vehicles, a small multi-bit driver or a compact set with interchangeable bits provides flexibility without bulk. Consider a driver with a comfortable, non-slip grip, and ensure the tips are high-quality to resist wear. A lightweight, portable set keeps your toolkit ready for quick repairs on the road or at home, where your license plate often lives.

If you already own a basic toolkit, you can start with a Phillips #2 and a flathead that fits the typical slot width. As you gain experience, you can add Torx bits and a magnetic screw holder to round out your setup. Remember: the right combination saves time and reduces the risk of damage to fasteners or the plate.

Replacing license plate screws and hardware options

When replacing screws, prioritize corrosion resistance and compatibility with your plate material. Stainless steel screws are a common choice due to their durability and resistance to road salt and humidity. Match the head type to your existing screws to maintain a clean, uniform look. If the existing screws show signs of rust or head damage, replace them with new screws of the same type and a slightly coarser thread if you’re installing onto thicker mounting points. If your plate or mounting brackets show signs of wear, consider replacing any stripped or bent hardware to ensure a secure fit and prevent vibration that could loosen the plate over time.

Keep spare hardware in a small bag or tray, using the same head type for consistency across all fasteners. For outdoor plates, consider weather-resistant coatings or self-locking nuts to minimize loosening due to vibration. Always tighten evenly and avoid overtightening, which can strip threads or distort the plate.

Troubleshooting common issues

License plate work can encounter hiccups: stripped screw heads, rusted screws, or screws that won’t budge. If a head is stripped, stop and switch to a fresh bit that seats snugly; apply light, steady pressure and try again. For stubborn rusted screws, apply penetrating oil and gently work the screw back and forth rather than forcing it. If a screw head breaks off, you may need to extract the remaining shaft with a screw extractor or consult a professional. Never resort to brute force—the surrounding paint and mounting holes are easy to damage when you push too hard. Finally, after reattaching, test the plate by gently pulling to ensure it’s secure and aligned with the bumper lines.

By anticipating these issues and using the right tools, you’ll minimize damage, save time, and keep your license plate firmly in place.

What to keep in your toolbox for future license plate fixes

A small, dedicated license plate toolkit saves time on the next repair. Keep a Phillips head, a Flathead with options, a Torx driver, a magnetic tip, a small tray for screws, painter’s tape for protection, a few spare stainless screws, and a compact flashlight. Label any mission-critical screws for quick reassembly and consider carrying a compact multi-bit driver so you’re prepared for unusual head types without needing to search through a full toolbox. A tidy, organized kit also reduces the chance of cross-threading or misplacing fasteners when you’re in a tight space.

Storing your tools in a dedicated compartment makes it easier to locate the right bit for future plate maintenance, ensuring you’re always ready for routine maintenance or emergencies on the go.

Authority sources

- Authoritative safety and tool-use guidance: https://www.osha.gov

- Educational extension guidance on basic hardware and maintenance: https://extension.illinois.edu

- Practical consumer information on tool use and maintenance: https://www.consumerreports.org

These sources provide general safety practices and practical considerations for tool use and maintenance, which complement the hands-on guidance in this article.

Tools & Materials

- Phillips screwdriver #2(Fits most license plate Phillips screws)

- Flathead screwdriver (width to slot)(Use a precise width to avoid slipping)

- Torx screwdriver (e.g., T-15 or T-20)(Only if your screws show Torx head marks)

- Magnetic screwdriver or magnetic bit(Keeps screws from dropping into crevices)

- Magnetic tray or small dish(Organizes screws during removal)

- Painter's tape(Protects surrounding paint and trim)

- Replacement screws (stainless, matching head type)(Ready if original screws are worn or corroded)

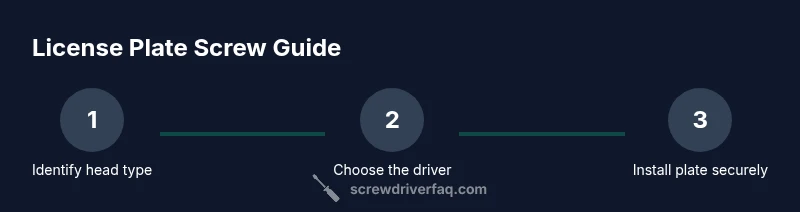

Steps

Estimated time: 30-45 minutes

- 1

Identify screw head type

Inspect the license plate screws to determine whether the head is Phillips, flathead, Torx, or a specialty security head. Look for the shape on the screw head and any markings. This step prevents guessing and reduces damage from trying the wrong bit.

Tip: Use a bright light and a magnifying glass if needed to spot subtle details. - 2

Choose the correct screwdriver

Match the head type to the screwdriver tip size. For Phillips, a #2 is common; for flathead, pick a width that fits the slot; for Torx, use the correct size. Using the right bit minimizes cam-out and head damage.

Tip: If you’re unsure, start with the most common driver and test gently before applying full torque. - 3

Prepare the plate and working area

Park on a flat surface, turn off the engine, engage the parking brake, and clean around the plate. Place painter’s tape to protect nearby paint and use a magnetized tray to keep screws organized. A clean workspace reduces misplaced fasteners and accidental scratches.

Tip: Have a helper hold the plate steady to prevent bending during removal. - 4

Remove the screws

Turn slowly with steady, even pressure to back out the screws. If a screw resists, back it out a quarter turn, then continue. Avoid twisting hard to prevent head stripping or thread damage.

Tip: If a screw binds, stop and re-evaluate the head type rather than forcing it. - 5

Inspect screws and plate condition

Check for rust, stripped heads, or damage. Replace with stainless screws if needed and ensure mounting holes are not elongated. This step ensures long-term security and reduces the risk of future failures.

Tip: Replace any corroded fasteners with compatible stainless hardware. - 6

Install plate securely

Align the plate and insert screws, tightening evenly in a simple, uniform pattern. Do not over-tighten, which can strip threads or crack the mounting bracket. Recheck the alignment after a partial tighten, then finish.

Tip: Tighten gradually and test the plate’s rigidity after final engagement.

Quick Answers

What screwdriver should I use for license plate screws?

Most license plates use Philips head screws and can be removed with a Phillips #2. If you see a flat slot, use a flathead. Some newer cars use Torx screws, so check the head pattern before applying force.

For most plates, use a Phillips #2. Check the head pattern first; if it’s a flat slot or Torx, switch bits accordingly.

Can I use a multi-bit screwdriver for license plates?

Yes. A compact multi-bit driver can cover Phillips, flathead, and Torx heads. Ensure each bit is securely seated before turning and avoid switching bits mid-task to prevent head damage.

A multi-bit driver works well as long as you seat the correct bit firmly before turning.

What if the screw head is stripped?

Stop and switch to a fresh bit that fits snugly. If the head is seriously damaged, you may need a screw extractor or professional help. For future tasks, replace damaged screws with stainless ones.

If the head is stripped, stop and try a new bit or seek professional help if needed.

Are license plate screws all the same size?

No. Screw size and thread can vary by vehicle and plate type. Always verify the head type first and match the screw length and thread to the mounting points.

Screw sizes vary; verify head type and match length and thread to your plate mount.

Should I upgrade to stainless screws?

Stainless screws resist corrosion and are a common upgrade for exterior plates. Ensure you select the correct head type and length for your mounting holes.

Upgrading to stainless is a good idea for durability; ensure proper head type and length.

The Essentials

- Identify head type before choosing a driver.

- Use the correct screwdriver for clean removal.

- Protect the vehicle finish during work.

- Replace damaged screws with corrosion-resistant options.

- Organize hardware for quicker reassembly.