How to Make a Screwdriver: A Practical DIY Guide for Beginners

Learn how to make a screwdriver from basic materials with steps for shaping the handle, forming the blade, and testing torque. Includes tools, safety tips, and basic maintenance for DIY enthusiasts.

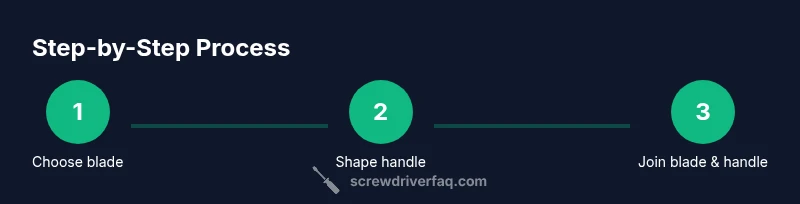

Goal: learn how to make a simple, functional screwdriver and understand safety basics. This guide covers selecting components, shaping a handle, attaching a blade, and testing for torque and safety. You’ll need a steel rod, a blade profile, a handle material, a ferrule or cap, and basic tools. Follow step-by-step instructions, plus tips to avoid common mistakes.

Understanding the concept of making a screwdriver

If you're exploring screwdriver how to make, this guide covers the philosophy, safety, and practical methods behind crafting a basic tool. The process blends metalwork, ergonomics, and simple assembly to create a tool you can trust for light-to-moderate tasks. According to Screwdriver FAQ, starting with a straightforward straight-blade design helps beginners focus on grip, alignment, and safe handling. You’ll learn how to choose a blade profile that matches your most-used screws, shape a comfortable handle, and secure the blade so it won't loosen during use. Beyond the blade, the build emphasizes a reliable grip and balanced weight to reduce fatigue over long projects. The DIY mindset here is to prototype, test, and improve with repetition, not to chase perfection on the first try. Keeping safety gear handy and working at a clean, well-lit bench will help you avoid common mistakes and accidents as you experiment with materials and finishes.

Understanding the concept of making a screwdriver

Tools & Materials

- Steel blade stock or rod (high-carbon steel)(Choose a straight-blade profile close to standard slotted screwdriver dimensions.)

- Handle material (wood, hard rubber, or durable plastic)(Prefer grips with a gentle taper for comfort and control.)

- Ferrule or cap(Helps lock blade and handle alignment and provides a finished look.)

- Epoxy or strong adhesive(Use a two-part epoxy for a secure blade-to-handle bond.)

- Drill and drill bits (appropriate size)(For creating pilot holes or tang features as needed.)

- Metal file or fine grinder(For shaping blade profile and smoothing edges.)

- Safety gear (gloves, safety glasses)(Protect hands and eyes during cutting and grinding.)

- Measuring tools (ruler or calipers)(Helpful for precision, not strictly required.)

Steps

Estimated time: 60-90 minutes

- 1

Select and prepare the blade profile

Choose a blade profile (flat/slotted is simplest) from stock or grind a straight edge from a steel rod. Mark the desired length, then rough-cut to approximate shape. File or grind to create a clean, straight edges with a square tip.

Tip: Keep the edge cool while grinding to avoid tempering the steel; dip in water as needed. - 2

Shape the handle for comfort

Cut a handle blank from your chosen material or machine a grip that fits your hand. Ensure the diameter matches your palm for secure control and marks for finger placement to reduce fatigue during use.

Tip: Test grip frequently by simulating work motions to avoid a handle that slips or causes cramp. - 3

Create the tang and join blade to handle

Drill a tang hole or shape a tang on the blade so it can be anchored in the handle. Apply epoxy to the mating surfaces and insert the blade, aligning tip and handle axis before the adhesive cures.

Tip: Wipe away excess epoxy and keep the assembly clamped steady to prevent misalignment. - 4

Attach ferrule and align components

Slide on a ferrule or cap to lock the blade and handle orientation. Ensure the joint sits flush and there are no gaps that could allow blade movement.

Tip: Check clearance with the shaft at multiple angles to confirm stability. - 5

Finish and sharpen edges

Lightly deburr all rough edges and apply a rust-preventive finish if the blade is exposed metal. Sharpen or bevel the tip to a precise edge suitable for the intended screws.

Tip: Avoid removing too much material near the tip; a smaller, well-defined edge performs better. - 6

Test torque and safety

Grip the assembled screwdriver and test on spare screws in a safe environment. Check for twist, wobble, or blade movement and re-secure joints if needed.

Tip: Use a soft jaw vise or clamps when testing pressure to prevent accidental slips.

Quick Answers

Is it safe to make my own screwdriver?

DIY screwdriver projects can be safe if you use proper materials, take your time, and wear protective gear. Avoid using compromised blades or improvised handles that slip or break under load.

Yes, with the right materials and safety practices, but take your time and use protective gear.

What blade profile works best for most screws?

For general tasks, a straight-blade (slotted) profile is simplest and versatile. Specialized tasks may require Phillips or Robertson profiles, but these are more complex to craft.

A straight-blade grip is usually enough for most home tasks; switch to other profiles for specific screws.

Do I need heat treatment for the blade?

Heat treatment can improve hardness and edge retention but adds complexity. For beginners, selecting a hardened stock and careful grinding is often sufficient for light work.

Heat treatment improves durability but is optional for basic DIY projects.

Can I reuse an old shaft or tool as a blade?

Reusing an old shaft is possible if it has a straight profile and remains hard enough after test grinding. Check for cracks or corrosion before planing new edges.

You can reuse a sturdy shaft if it’s straight and undamaged; inspect first.

What are common mistakes when making a screwdriver?

Poor blade alignment, weak joints, and slippery handles top the list. Rushing the curing process or grinding too aggressively can ruin edge precision.

Misalignment, weak joints, and poor grip cause most issues; take time to verify fit.

Is making a screwdriver cost-effective compared to buying one?

For casual projects, DIY can be cost-effective when you already own the tools. For high-volume or professional use, a purpose-built handle and blade set may be more economical.

DIY saves money for occasional use, but consider time and tool costs for frequent use.

The Essentials

- Plan the blade and handle as a single ergonomic unit.

- Securely bond blade to handle with appropriate adhesive.

- Prioritize safety gear and controlled finishing processes.

- Test fit and torque to ensure long-lasting performance.