How to Magnetize a Screwdriver: A Practical Guide

Learn safe, proven methods to magnetize a screwdriver for easier screwdriving. This guide covers stroke techniques, magnetizers, testing, maintenance, and safety tips for DIYers and homeowners.

To magnetize a screwdriver, you’ll create a temporary magnetic field that attracts metal and holds screws during work. Choose a strong magnet or magnetizer, wipe the tip clean, and stroke the magnet along the shaft in one direction several times. For longer-lasting effect, repeat as needed or use a dedicated magnetizer.

How magnetism works on screwdriver tips

If you're wondering how to magnetize screwdriver, the basic idea is simple: you expose the steel tip to a strong magnetic field, which aligns the tiny magnetic domains inside the metal. When those domains align with the field, the tip becomes a temporary magnet capable of attracting screws and metallic shavings. The degree of magnetization depends on the steel’s composition, heat history, the strength of the magnetic source, and how long you apply exposure. According to Screwdriver FAQ, magnetizing tools is a practical skill for DIYers that speeds up many common tasks. The goal is to create a reliable, short-term magnetic field that helps you start a screw without dropping it, while avoiding excessive residual magnetism that could affect nearby fasteners or electronics.

Quick overview of magnetization methods

There are several practical routes to magnetize a screwdriver, ranging from simple to more controlled approaches. The most common methods fall into four categories: (1) stroke-based magnetization using a magnet, (2) using a dedicated magnetizer, (3) plate or bench methods that expose the tip to a strong, extended magnetic field, and (4) electrical or advanced techniques for higher retention. For most DIY tasks, a handheld magnet or magnetizer is more than enough. Remember that magnetization is strongest at the tip and gradually diminishes toward the handle. In addition, heat and shocks can reduce magnetization, so it’s best to magnetize only when you need it and test before heavy use.

Method A: Stroke a magnet along the shaft

The classic, low-cost way to magnetize a screwdriver is to stroke a strong magnet along the shaft in one direction. Start with a clean, dry tip. Hold the magnet firmly and run the tip from near the handle toward the tip, brushing in a single direction for 20–40 passes. After each pass, wipe away any metal filings and check the hook by attempting to lift a small screw. This method creates a temporary alignment of magnetic domains within the steel and is ideal for quick jobs. If you want a longer-lasting effect, you can repeat the strokes after a short break. Pro tip: always stroke in the same direction to avoid creating a focal region of magnetization that could be uneven.

Method B: Use a magnetizer device

A dedicated magnetizer (or magnetizing tool) is designed to produce a stronger, more uniform magnetic field than a single magnet. Follow the device’s instructions, typically involving placing the screwdriver’s tip in or near a magnetic chamber and activating the magnetization cycle. After the cycle, test the tip by lifting a screw. This approach is especially useful if you do a lot of screwdriving or need a more consistent hold across multiple tasks. If you don’t own a magnetizer, the handheld stroke method remains a very effective alternative.

Method C: Plate or bench magnet technique

For a stronger, more uniform magnetization, you can use a ferromagnetic plate or a steel surface as a source of magnetism. Place the screwdriver tip flat on the surface and move it in one direction across the plate several times. The plate is magnetized and provides a broader magnetic field that can improve the retention of the tip. This method is particularly helpful when you want a longer-lasting effect without repeatedly stroking a single magnet. Always ensure the plate itself isn’t corroded or magnetized unevenly to avoid inconsistent results.

Method D: Electrical magnetization (advanced)

An advanced approach involves creating a controlled magnetic field using a coil and power source. This technique can yield stronger and more uniform magnetization but carries more risk and requires careful handling to avoid overheating the screwdriver or damaging nearby electronics. If you’re not familiar with basic electronics, skip this method and stick to mechanical magnetization methods or a professional magnetizer. When attempting any electrical method, work in a well-ventilated area and disconnect power when changing components.

How to test magnetization and measure strength

Testing magnetization is simple and can be done with everyday screws. Hold the screwdriver near the head and see if it can attract a loose screw with minimal effort. A stronger magnetization should lift screws more reliably and hold them longer. For a practical DIY test, try lifting a handful of screws of similar size and note how quickly the magnet loses grip. If magnetization weakens after a few minutes, reapply one of the methods above. Regular checks ensure you don’t rely on a weak magnet when you need it most.

Maintaining magnetization and avoiding demagnetization

Magnetization can fade with heat, impact, or close exposure to other magnets. To preserve your magnetized screwdriver, avoid dropping it, keep it away from high-heat environments, and store it away from magnetic-sensitive devices. If your task requires long-term magnetization, consider using a magnetizer device designed for durability or performing periodic re-magnetization. When you’re done, wipe the tip to remove debris and protect the edge from chipping, which could alter the magnetization pattern. Regular gentle use tends to maintain practical magnetism without risking damage to the tool.

Safety considerations and best practices for magnetizing tools

Always exercise caution around electronic devices and sensitive storage media, as strong magnets can erase data or interfere with electronics. Keep magnets out of reach of children and away from credit cards, watches, and other magnetically encoded items. Wear eye protection if you anticipate any fragments or shavings during the process. Finally, remember that magnetization is usually temporary and can degrade with time and use; plan to re-check and re-magnetize as needed.

Tools & Materials

- Strong bar magnet (neodymium recommended)(At least 1 inch long; avoid weak magnets near small screws)

- Magnetizer device (optional)(Useful for higher consistency and longer-lasting magnetization)

- Lint-free cloth(Wipe the tip clean before magnetizing)

- Ferromagnetic plate or steel surface (optional)(Use for plate method to enhance magnetic field)

- Safety gear (glasses, gloves)(Protect eyes from shavings and fingers from pinching magnets)

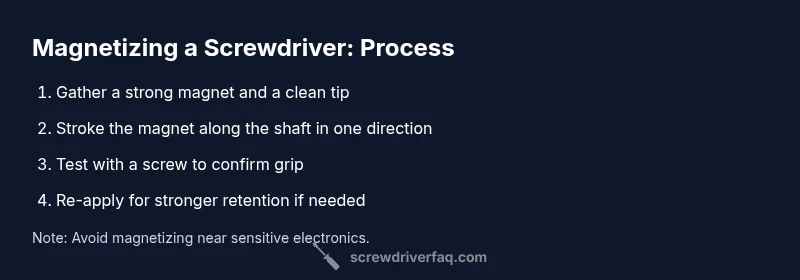

Steps

Estimated time: 15-25 minutes

- 1

Gather supplies and prepare workspace

Collect a strong magnet or magnetizer tool and clean, dry workspace. Ensure there’s a stable surface and good lighting so you can see the tip clearly. This initial setup minimizes accidental slips and ensures consistent magnetization.

Tip: Pro tip: keep magnets away from electronics and cards during setup to avoid data loss. - 2

Clean the screwdriver tip

Wipe the tip with a dry, lint-free cloth to remove oil and debris. A clean surface allows the magnetic domains to align more evenly and reduces the chance of contaminants interfering with the magnetization process.

Tip: Pro tip: a quick wipe improves results and helps prevent grit from dulling the edge. - 3

Stroke the magnet along the shaft (same direction)

Hold the magnet firmly and stroke the tip from near the handle toward the tip in one steady direction. Do this 20–40 passes, maintaining consistent pressure and motion. This creates a directional magnetic field that aligns domains in the steel.

Tip: Pro tip: keep the magnet parallel to the shaft to maximize contact area. - 4

Test magnetization with a screw

Place a loose screw near the tip and observe whether the screw sticks and lifts with moderate effort. If it barely holds, you may need another round of stroking or switch to a magnetizer for stronger results.

Tip: Pro tip: use screws of similar size to ensure a fair test. - 5

Repeat strokes for stronger magnetism

If the first test is weak, repeat the stroke process in the same direction for another set of passes. Allow a brief pause between cycles to prevent overheating of the magnet and the metal.

Tip: Pro tip: avoid excessive force; persistent stroking is more effective than heavy pressure. - 6

Try the magnetizer device (optional)

If you have a dedicated magnetizer, follow the device instructions to magnetize the tip. This method can produce a more uniform field and longer-lasting magnetization, especially for frequent screwdriving.

Tip: Pro tip: always read the user guide before using a magnetizer to avoid improper use. - 7

Use the plate method for stronger field (optional)

Place the screwdriver tip on a ferromagnetic plate and move it across the surface in one direction several times. The plate’s magnetic field can enhance consistency across attempts and is useful when you require steadier magnetism.

Tip: Pro tip: ensure the plate is clean and free of corrosion for better results. - 8

Store and maintain magnetization

After magnetizing, store the screwdriver away from other magnets and heat sources. Regular checks and occasional re-magnetization help maintain helpful strength for practical tasks over time.

Tip: Pro tip: a quick test with a screw before a big job confirms reliability.

Quick Answers

Will magnetizing affect the screwdriver's handle or ferrule?

Magnetizing primarily affects the metal tip; the handle and ferrule are usually unaffected if they are non-ferrous or not magnetically susceptible. For most common handles, magnetization remains localized to the tip area.

Magnetizing mainly affects the tip. Your handle and ferrule are typically fine, but test a small screw to be sure.

How long does magnetization last?

Retention depends on usage, heat, and impacts. Regular re-magnetization is common for frequent tasks, while occasional jobs may keep a temporary magnetization intact for longer during a project.

How long it lasts varies with use and heat, but you can re-magnetize as needed.

Can I magnetize any screwdriver?

Most steel-tipped screwdrivers are magnetizable. Some handles or tips may be case-hardened and resist magnetization to some degree, but the majority will respond to standard methods.

Most steel tips magnetize fine, but a few high-hardness tips may resist a little.

What magnet should I use for best results?

A strong, stable magnet such as a neodymium bar magnet is a reliable option for quick magnetization. A dedicated magnetizer can provide more consistent results for frequent use.

A strong bar magnet works well, and a magnetizer can offer more consistency.

Can magnetized tips damage electronics?

Strong, nearby magnets can affect sensitive electronics. Keep magnetized tools away from hard drives, credit cards, and other magnet-sensitive devices.

Keep magnetized tools away from electronics and magnetic data storage.

Is there a risk of demagnetizing other tools nearby?

Yes, strong magnets can affect nearby ferromagnetic tools. Store magnetized screwdrivers away from other metal tools if possible and avoid stacking them with magnets.

Store magnetized tools separately to prevent affecting other metal items.

The Essentials

- Understand that magnetism in screwdrivers is practical, not permanent.

- Use a strong magnet or magnetizer for best results.

- Test with screws to verify grip before use.

- Protect nearby electronics and cards from magnetic fields.

- Regularly re-magnetize as needed for ongoing utility.